2020-

Engineering and

Software Solutions

for CFD and FEA

Your are here: Our Products > Simulation Tools

DHCAE Tools has developed extensions for the renowned CFD toolbox OpenFOAM® to enable the dedicated modelling of disintegration and spray applications. These extensions facilitate the comfortable and professional use of open-

All-

for open source solver technology

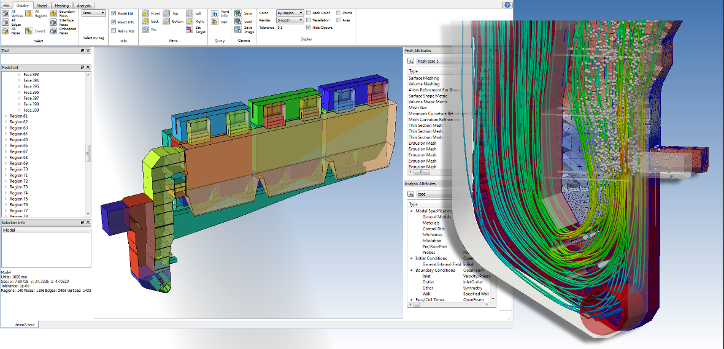

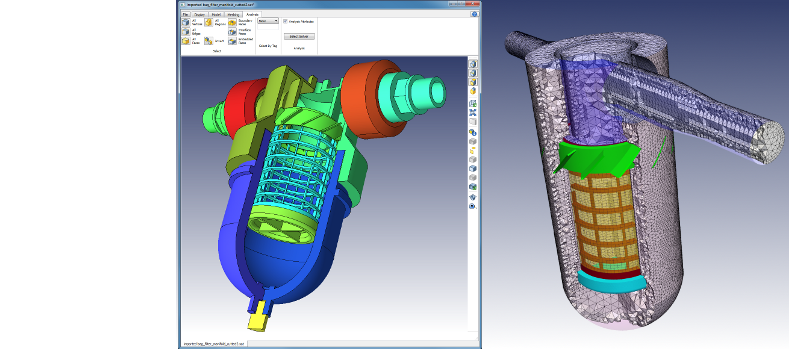

DHCAE Tools supports the whole CFD/FEA workflow: software additions (CastNet), services, training courses, support and solver extensions.

Initial disintegration -

In liquid decay processes, surface waves are first formed starting from an injector. From here larger, mainly separated liquid areas (ligaments) are formed, which then decay into smaller particles. During the initial wave break-

Spray propagation with Lagrangian particle tracking (LPT)

Once many small spherical droplets have formed, it is usually computationally impossible to resolve each individual droplet through several grid cells in order to model the spray dispersion. For this purpose, a transition model from VoF to Lagrangian particles (also referred to as VoF to DpM) was created in order to model the entire process from the disintegration of the liquid to the spray propagation.

Successfully used in many industrial applications, e.g.:

- AdBlue atomisation from multiple nozzles:

Single fluid atomisation from pressure swirl nozzles

- Paint atomisation:

Twin fluid atomisation of shear thinning liquids with transonic gas jets

- Car wash applications:

Single fluid atomisation of water from flat spray nozzles

- Liquid melt atomisation for metal powder and steel shots

Twin fluid atomisation with transonic gas jets and liquid solidification

Realistic prediction of spray angles, droplet sizes and spray density

Very good agreement was achieved between simulation and experiment e.g. in various benchmarks and industrial customer cases.

Examples:

- Twin fluid atomisation Liquid jet in cross flow

- Single fluid atomisation: Liquid jet from a hole nozzle

- Ethanol atomisation from a swirl nozzle

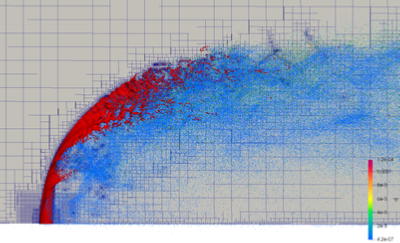

Transition modelling VoF to Lagrangian particle tracking (LPT)

DHCAE has extensively extended the computational methods of OpenFOAM to realise a conversion of disintegrating fluid regions (VoF method) into a discrete particle description. This enables a closed modelling of

- Atomisation processes

- Spraying processes

- Injection applications

- General disintegration processes of liquid jets into small droplets.

The implementation is characterised by

- a high degree of accuracy, e.g. with regard to the transmitted forces or conservation quantities,

- a particularly computationally efficient realisation for grid refinement and particle transport through special partitioning procedures and a high degree of parallelisation, as well as

- stable and reliable simulation processes with extensive monitoring (e.g. particle sizes, spray angles, etc.).

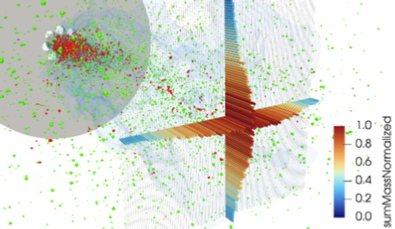

Transition from VoF areas (red) to Lagrangian particles (green) during atomisation from a swirl nozzle

Comparision of the lamellar shape and spray angle: Flat spray nozzle for car wash application

Adaptive grids and particle cloud in the liquid jet in cross flow benchmark -

Liquid metal atomisation for powder generation: Pressure swirl configuration with high-

Liquid metal atomisation for powder generation: The interaction of ligaments and high-

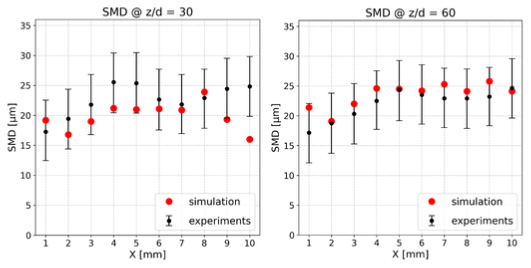

Comparison:

Deflection of jet in animation (comparison with min/max/mean exp. data)

Right figures:

Particle sizes at 30d and 60d

Reference: Sekar J., et. al. “Liquid jet in cross flow modelling” In Proceedings of ASME turbo expo 2014: turbine technical conference, Düsseldorf, Germany; 2014.

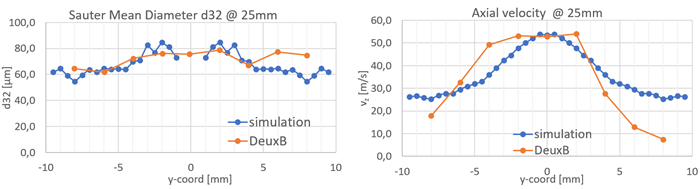

Example 2: Comparison simulation-

Liquid jet atomisation from a hole nozzle

Comparison: Droplet sizes and velocities, both experimental and numerical, at a distance of 25 mm.

Comprehensive spray diagnostics:

Particle data (e.g. sizes, velocities, temperatures) and spray density can be determined as profiles in different planes.

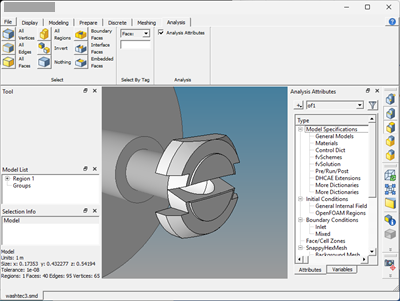

Optional extras: A GUI with predefined templates for various atomisation applications.

Reference: Deux E. „Berechnung der turbulenten Zerstäubung von Flüssigkeiten durch Kombination eines Zweifluidmodells mit dem Euler-

Example 1: Comparison simulation-

Liquid jet in cross flow

See more examples in our atomisation/spray playlist on our YouTube channel.

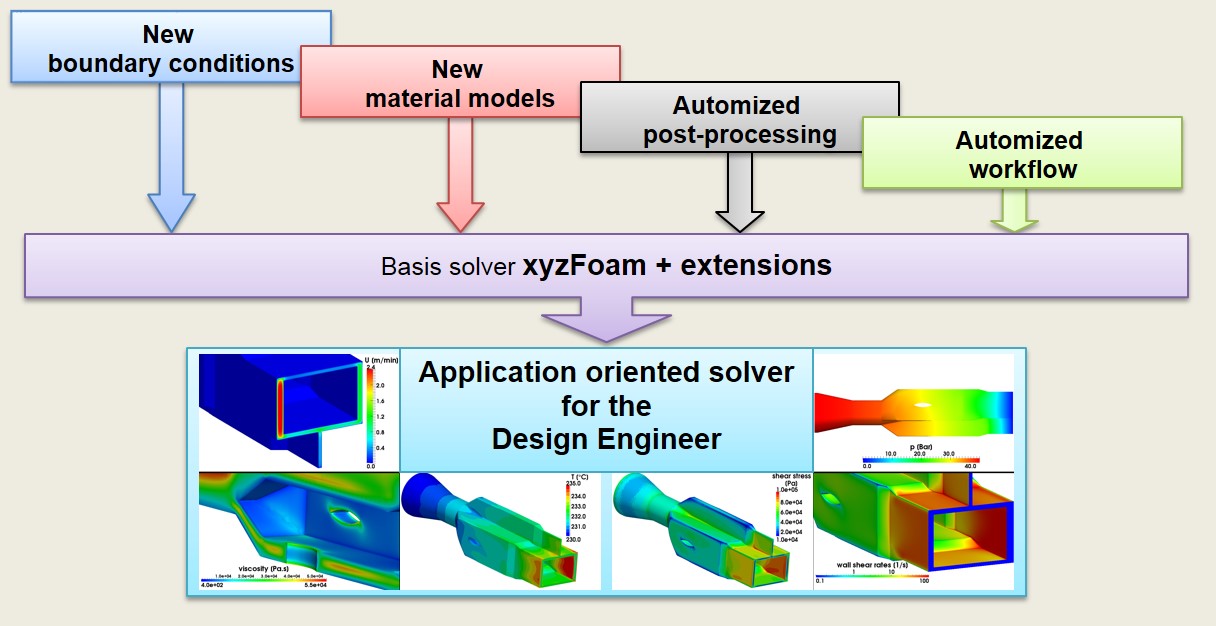

In addition to CFD simulation and consulting services, we also provide the solver for in-

The solver can be deployed flexibly on an arbitrary number of compute systems as well as in HPC environments.

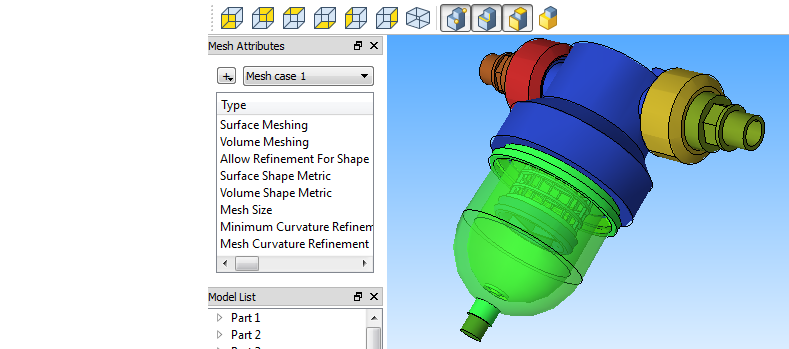

The delivered package includes comprehensive GUI-

Optionally, the system can be extended by a fully GUI-

For more information please contact us!

Example 3: Swirl atomisation of ethanol with excellent agreement of particle size with an empirical comparison.